Have a look at the industry work I have done in my career so far and the experience I have achieved.

Howard McCray

- Designed and developed mechanical components and assemblies for commercial refrigeration systems, focusing on structural integrity, thermal performance, and manufacturability.

- Led DFM, DFA, and Design for Serviceability initiatives to reduce assembly time, improve field maintainability, and lower overall production costs.

- Conducted hands-on prototyping and manufacturing support, working directly on the shop floor to validate designs, troubleshoot issues, and implement engineering changes.

- Collaborated with manufacturing engineers to introduce design modifications that improved product performance, durability, and production throughput.

- Worked on producing drawings, BOMs, and production-ready documentation, for production and sales.

- Managed communication with suppliers and vendors to source components, address manufacturability concerns, and ensure design compliance with cost and quality targets.

- Supported cross-functional engineering projects from concept to production, ensuring alignment with deadlines, technical requirements, and quality standards.

- Implemented 5S workplace organization and supported safety improvements, enhancing efficiency and safety.

Skills/Knowledge Acquired:-

- Commercial Refrigeration Systems Design

- SolidWorks/CAD Production Drawing

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- Design for Serviceability

- Hands-on Prototyping & Validation

- Engineering Change (EC) Implementation

- Bill of Materials (BOM) Management

- Production Throughput Optimization

Holtec International

- Designed storage & transport containers, using SolidWorks for storage & disposal of spent nuclear fuel, as per client requirements.

- Designed ancillary equipment; like lift yokes, lifting rigs, and transporters, required for safe handling of the containers.

- Edited and improved existing drawings and designs as per client requisites, regulations, or mechanical analysis results.

- Maintained drawings, designs, and models systematically in PDM storage for ease of access and efficient editing.

- Collaborated with team members and members of other departments to produce high-quality drawings.

- Created a flushing loop system for large-scale heat exchangers with a 4500-gallon capacity to clean heat exchangers.

- Redesigned the cask transporter to reduce manufacturing costs by $150k while improving its strength by 8%.

Skills/Knowledge Acquired:-

- Designing on SolidWorks

- Geometric Dimensioning and Tolerancing

- Creating and reviewing design drawings

- Developing conceptual models

- P&ID drawing creation

- Attention to detail and problem-solving

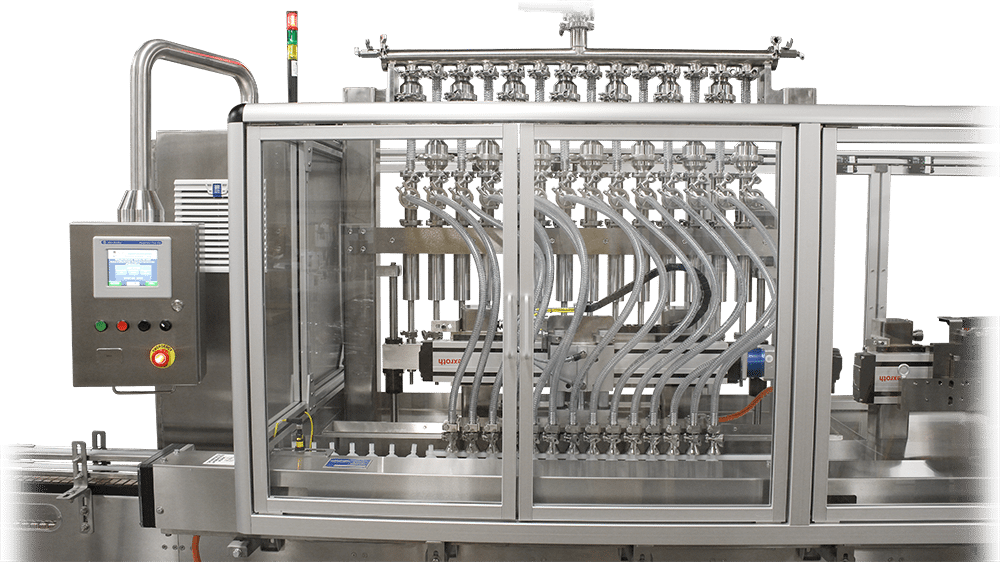

Veracity International

- Maintained and operated the automatic bottle filling line: improved process cycle time by 15% by optimizing the overall process.

- Improved the alignment and process flow of the line to improve cycle time and lead to fewer errors during production.

Skills/Knowledge Acquired:-

- Bottle filling process and its maintenance

- Optimization of the production line

- Attention to detail and problem-solving

Colinear Machine & Design

- Developed programs for CNC milling machines to manufacture complex aluminum and steel parts, using a variety of tools.

- Designed fixtures, using AutoCAD, for the part being manufactured to facilitate further operations of manufacturing.

- Applied geometric dimensioning and tolerancing concepts to the manufacturing process to make parts within a tolerance of ± 0.127mm.

- Inspected parts and maintained quality by using various tools like coordinate measuring machines, gauges, and indicators.

- Teamed up with machinists to streamline manufacturing operations and manufacture parts that match quality standards.

Skills/Knowledge Acquired:-

- Modeling and designing on AutoCAD

- Working and set-up of CNC machines

- CNC programming using G&M Codes

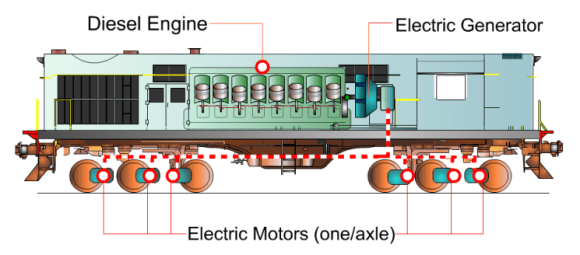

Central Railway Loco Workshop

- Investigated working of pneumatic actuation circuit for heavy-duty locomotive braking systems: identified leakages and errors

- Redesigned bends of the pneumatic system on SolidWorks: reduced the joints by 25% following a reduction in fuel wastage by 3%

- Applied geometric dimensioning and tolerancing (GD&T) concepts that improved the braking system of the locomotive diesel engine.

Skills/Knowledge Acquired:-

- 3D Modelling

- Heavy-duty braking systems and their assembling

- Attention to detail and problem-solving

Air India Engineering Services Ltd.

- Involved in repairing & overhauling activities of small body airplanes: developed FMEA reports of turbofan engine blades.

- Applied repairs and quality checks to turbofan engine blades to maintain balancing of shaft and plane’s HVAC systems.

- Maintained BOM of repaired parts: Assisted in assembling the repaired components – reduced cycle time by 7.5%.

Skills/Knowledge Acquired:-

- CNC machining and tooling

- Onsite and offsite quality inspection

- Failure mode effect analysis

MAHAGENCO GTPS

- Interpreted process flow diagram of gas and steam turbines to identify usage of natural gas based on the state of the national grid.

- Performed the maintenance of gas turbines and all the corollaries that work as a system to generate electricity.

- Maintained various control parameters required for the economical and safe functioning of a gas turbine.

Skills/Knowledge Acquired:-

- Gas-powered systems and their accessories

- Electricity generation and management